SOAP WRAPPING MACHINES

SW 200

Low speed wrapper for soap bars (200 ppm)

-

Manage small production of soap

-

Handle big size formats of soap

-

Easy to operate, formats up to 200 GR

-

Delicate product handling

-

High packaging quality

-

Top performance in a compact layout

-

Soap handling and packaging process

-

Servo paper platform with reels

-

Optimized transport to preserve the product quality

-

Excellent sealing quality ensured with a broad variety of materials

-

Control panel and electronic system

-

Wrapping style and sizes

-

Rapid size changeover

-

Soap production line integration

SW 250/350

Wrapping machine for soap bars (250 ppm // 350 ppm)

Features as per the SW200, as well as the below:

-

Continuous operating mode

-

Automatic feeding system

-

Heat sealable packaging material

-

Point end fold/soap style packaging type

-

Suitable for rectangular & oval shape bars

-

High flexibility

SOAP PROCESSING

CONTINUOUS SAPONIFICATION PLANTS

More than 500 continuous saponification plants have been installed with plant capacities available from 3 to 20 tph:

– SCNT-N full boiled saponification with glycerine recovery

– SCT-U universal continous saponification plan for fatty acids neutralization and neutral oils saponification SWING

VACUUM DRYERS

More than 1.000 vacuum dryers have been successfully installed all over the world with plant capacities from 1 to 15 tph. The revolutionary “NO SPRAY” Vacuum Chamber was introduced during 2005: more than 150 units are in operation since then granting important production savings with simplified equipment design.

“PERFECT PLANT” SCTU-C

The “Integrated Process Plants”, first introduced more than 10 years ago, featuring a continuous saponification SCT-U directly connected with the “C” vacuum dryer allows flexible and versatile operations with consequent competitive manufacturing costs and significant utilities saving, friendly to the environment operation, limited maintenance and reduced area requirement.

The “Perfect plant” innovative design grants the most logical ergonomic set up with minimal installation area required, best piping/cable route, easiest operation.

The perfect plant layout permits adding at any time additional devices such as liquid/powder fillers dosing systems, superfatting agents, glycerin, dyes dosing systems the formulas may require without any space constraint nor layout modification.

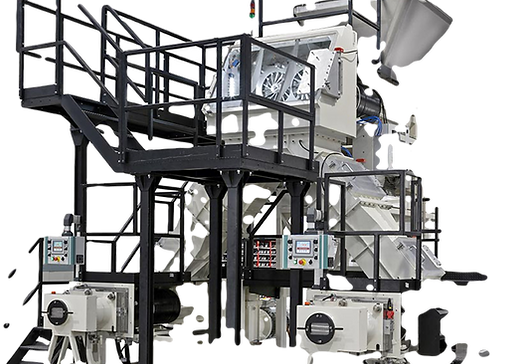

SOAP FINISHING LINES

A new generation of finishing lines to match the demand of manufacturing speeds from 100 to 1.400 bpm for small, medium, high and ultra high production with the best efficiencies.

The market demands to achieve the highest speeds, important energy and space savings, minimal manpower intervention and quickest line’s set ups: thanks to its continuous R&D program supported by a team of 40 engineers, we offers several innovative solutions to respond to the most sophisticated exigencies for quality soap bars making.

-

High efficiency Batch and Continuous Mixers/Amalgamators

-

New Plodders generation for capacities up to 15 tph

-

“Clean Design” hydraulic roll-mills

-

“Mechatronic” Electronic Cutters in single and duplo configuration

-

New concept soap presses with/without direct transfer system to packaging machines with stamping capacity up to 1.000 bars per minute

-

“MRP” Multi-refining Plodder, a single machine suitable to substitute a roll-mill (or duplex refiner) and a duplex vacuum plodder of a conventional finishing line with consequent energy, space, maintenance savings.